This website uses cookies to ensure you get the best experience on our website.

Read more

Resolving Common Issues with the PUL-1000 Puller

April 22, 2021

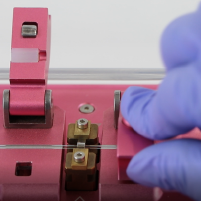

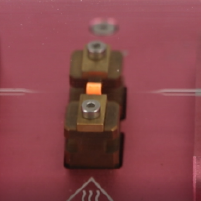

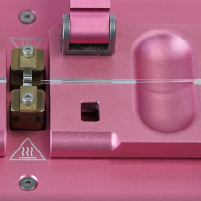

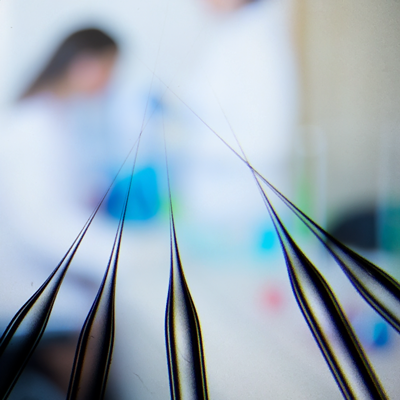

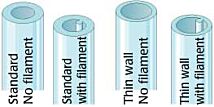

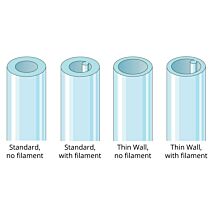

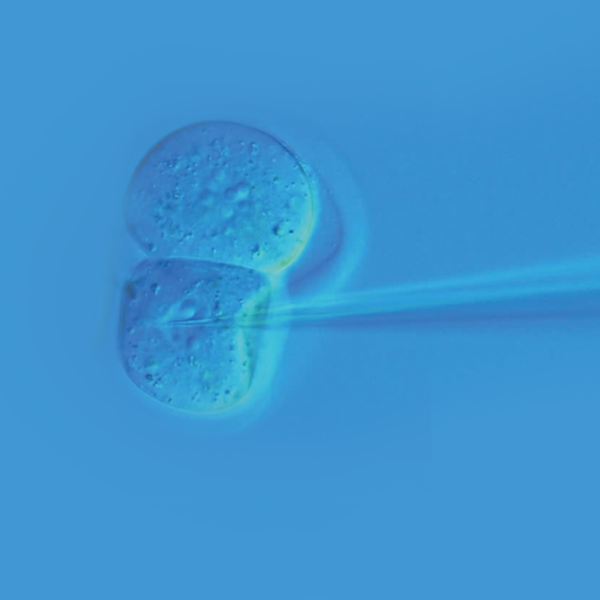

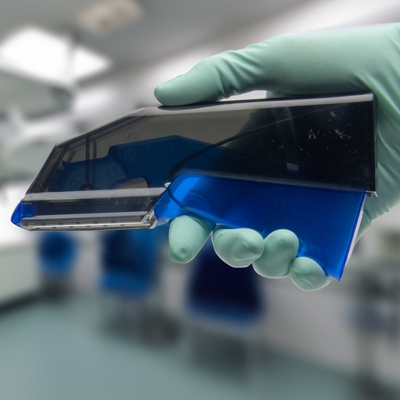

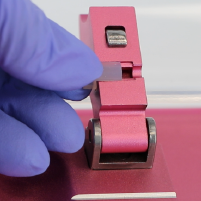

The PUL-1000 is a microprocessor controlled, four-stage, horizontal puller for making glass micropipettes or microelectrodes. Here are the resolutions for some common issues with the puller.

Puller Stops

If the puller stops in the middle of a pull and the unit beeps, one of two issues may be the culprit.

- The unit may be over heating. Allow the unit time to cool down before attempting to pull more glass.

- If a program fails in the middle of a pull, you may have exceeded the parameters of the unit. For example, when you add up the distance of travel for all the stages, you may have exceeded the maximum range of travel. Check your program. You may need to alter the heating or travel parameters to conform with the unit’s maximums.

Glass Doesn’t Pull Well

If the glass does not pull well, look at one of these possible causes.

- The parameter may not be set properly for the properties of the new glass. Run the Glass Softening Test to establish a new baseline heating parameter.

- The filament may be wearing out or may have broken. Install a new filament.

Cannot Select a Program

If you cannot select a program, the puller may be in Edit mode. It will not execute a program until you exit the Edit mode. Press the Exit key to exit the program editing mode without saving the program. Press Start to run your program.

Unit Beeps

If the unit beeps and the program fails to start, the carriages may be too far apart. Remove the glass, slide the carriages together and reposition the glass.

If you have any questions, just give us a call.

Close