This website uses cookies to ensure you get the best experience on our website.

Read more

Why Buy a PUL-1000 Research Puller for Making Micropipettes?

February 25, 2021

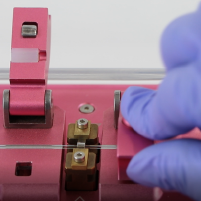

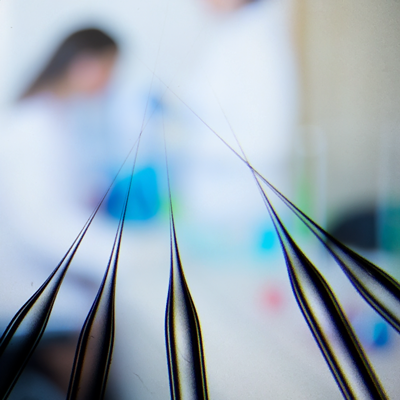

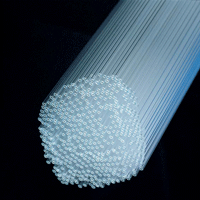

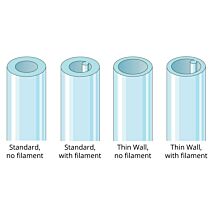

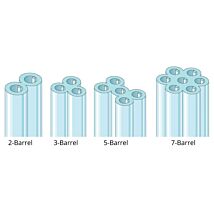

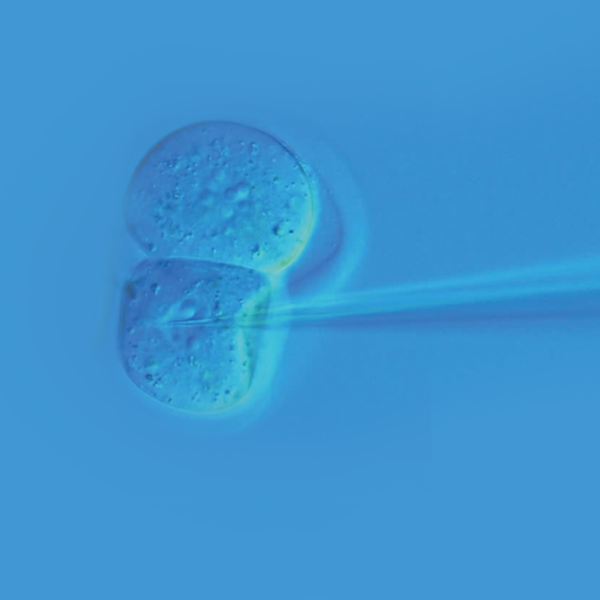

PUL-1000 is a microprocessor controlled, four-stage, horizontal puller for making glass micropipettes or microelectrodes used in intracellular recording, patch clamp, microperfusion and microinjection. The PUL-1000 is capable of producing a vast array of pipette shapes, such as a long graduated taper, a short graduated taper and a short taper bee stingers. Here's a quick introduction the PUL-1000 research puller.

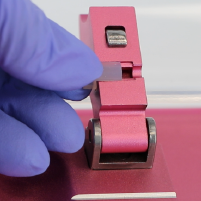

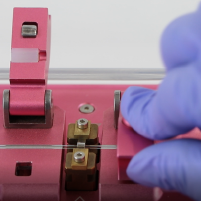

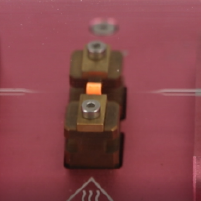

The PUL-1000 puller was designed with tight mechanical specifications and precision electronics for complete control of the pulling process and accurate reproducibility. It offers programmable sequences of up to four steps with heating, force, movement and cooling time. A glass capillary is heated by a platinum/iridium filament and pulled by a controlled force. The PUL-1000 is capable of producing a vast array of pipette shapes, such as a long graduated taper, a short graduated taper and a short taper bee stingers.

Programming

The settings for a 4-stage pull may be stored in memory. Up to 95 programs can be permanently stored in memory. The instrument contains 15 factory installed programs. Choose from the factory installed programs for a quick start or create your own for precise, custom results.

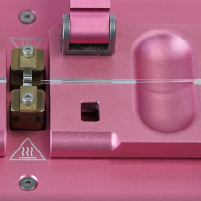

Construction

Tempered Glass Cover

The cover of the pulling chamber is made with tempered glass to minimize the effects of humidity and air currents on the reproducibility of pulled pipettes.

Switching Power Supply

The PUL-1000 has a switching power supply for use anywhere without worry about line voltage differences. Pulling reproducibility is unaffected by line voltage fluctuation. Heating voltage can be controlled to within 0.1% accuracy even when line voltage fluctuates from 100–240 VAC.

Educational/Research Puller

This puller is for educational and research purposes. It is not a production puller.

- Pulling tips less than 4 µm is easily repeatable.

- For consistent tip diameters greater than 5 µm, use a second operation like bevelling.

- When pulling glass tips finer than 1 um, first wash the glass capillaries in filtered acetone (or filtered distilled water and filtered 95% alcohol) then allow the fluids to evaporate in a clean dust free environment. This assures that sub-micron tips are not immediately clogged with glass particles from the manufacturing of the capillaries.

Glass capillaries can have slight difference between lots. Each time you open a new vial of glass capillaries, recalibrate the puller heat parameters for the new glass.

A Science and an Art

Pulling pipettes is a science and an art, and reliable results depend on factors like the operating environment, the type of glass used and your technique.The PUL-1000 can produce pipettes with a broad range of tip diameters and shapes.

If you have any questions, give us a call at (866) 606-1974 (Toll free in the USA) or email us at [email protected].

Close