This website uses cookies to ensure you get the best experience on our website.

Read more

Blog

-

April 09, 2024

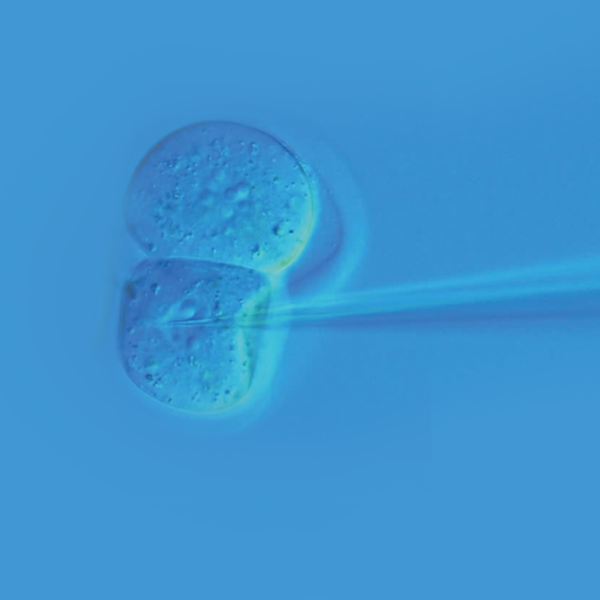

It has been found that transgenesis of vectors using Tol2 or other transposon-based systems promote stable expression. A standard pressure-based microinjection approach presents greater reliability, precision, and overall control when delivering material to embryos, often preferred over electroporation in zebrafish studies...more

-

March 20, 2024

World Precision Instruments (WPI) is pleased to announce their strategic partnership with TotalLab, paving the way for the integration of 21 CFR Part 11 compliance into its esteemed EVOM family of products...more

-

February 22, 2024

EVOM™ Auto, with both 24 and 96 HTS multiwell plate capability, is a high throughput screening (HTS) platform offering fast, noninvasive sample scanning by comparing electrical resistance measurements (transepithelial/transendothelial electrical resistance: TEER). TEER measurement experiments are simple to set up and less time consuming than more complex molecular studies. TEER measurement can be used as the primary scanning method to identify any physiological changes that can then be further evaluated by other methods. EVOM™ Auto can capture TEER measurements in 24 and 96 HTS multiwell plates from Corning, Millipore, or MatTek. The sample preparation time in these HTS plates is efficient, allowing for fast, multi-channel pipetting options.

The EVOM™ Auto autosampler ships with a red electrode array lock in place to prevent the electrode array connection port from moving during transit. Here you can see how to easily remove it without damaging the lock or the autosampler...more

-

February 19, 2024

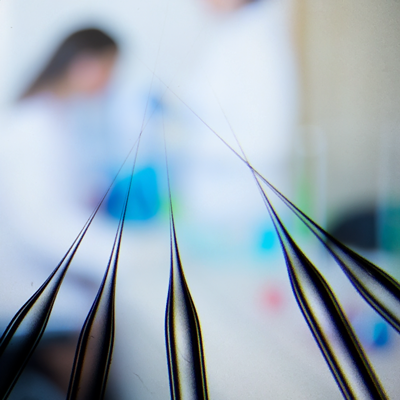

Below are some popular pullers from WPI, including Sutter pullers. Here we compare them so you can choose a system that is best suited for your application...more

-

February 16, 2024

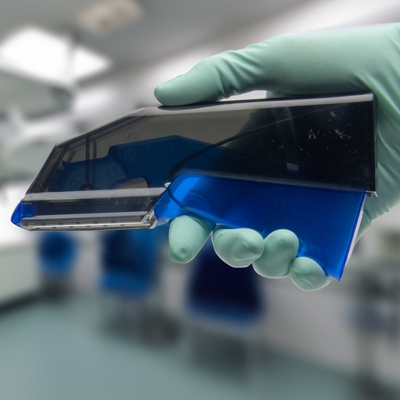

The WPSS01 skin stapler is an affordable, reliable solution for veterinary wound closures. A skin stapler is designed for the efficient closure of surgical incisions or wounds by applying surgical staples to the skin, reducing surgery time and time under anesthesia. Each disposable skin staple cassette contains at least thirty-five (35) 316L stainless steel staples.

Each reusable skin stapler handle is provided sterile with one disposable staple cassette already loaded into the handle. Discard the disposable staple cassette after the procedure. The reusable handle may be cleaned and resterilized (autoclave, EO) for subsequent procedures and will effectively deploy at least twenty (20) disposable staple cassettes and withstand at least twenty (20) autoclave cycles...more

-

February 06, 2024

Surgical forceps are available in several different grades, including disposable, standard stainless steel, German steel, Swiss made, and titanium. Your choice of instrument grade will depend on your requirements and your budget. Here are some considerations to help you make an informed decision...more

-

February 02, 2024

Choosing a dependable lab equipment supplier is crucial for ensuring the quality, reliability, and timely delivery of the equipment you require. When your research is on the line, you need a company you trust, a supplier with a proven track record and a service team to back you up. Here are a few important considerations when selecting a lab equipment supplier...more

-

January 30, 2024

Reducing hand fatigue while using surgical scissors is important, not only for your comfort, but also to maintain the precision of your work. Here are some tips to help reduce strain and minimize hand fatigue...more

-

January 23, 2024

Metzenbaum and Mayo scissors are both types of surgical scissors, and while they may look similar at first glance, they serve different purposes. Let’s look at the differences between the two scissors styles...more

-

January 16, 2024

Surgical forceps are available in several different grades, including disposable, standard stainless steel, German steel, Swiss made, and titanium. Your choice of instrument grade will depend on your requirements and your budget. Here are some considerations to help you make an informed decision...more