This website uses cookies to ensure you get the best experience on our website.

Read more

Product Information

-

April 09, 2024

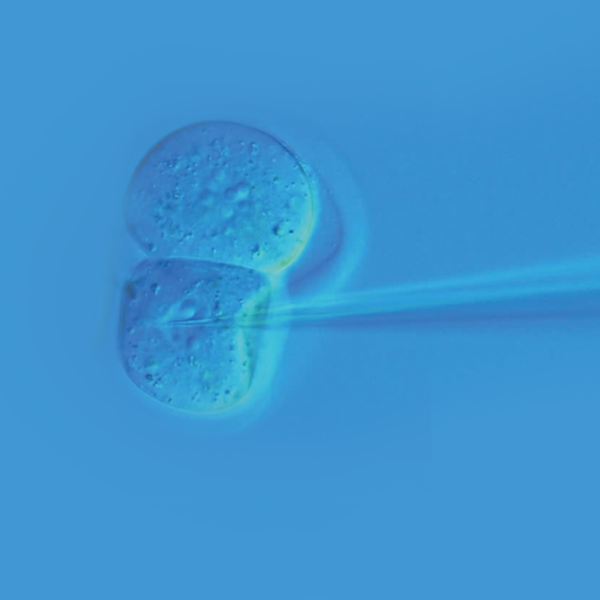

It has been found that transgenesis of vectors using Tol2 or other transposon-based systems promote stable expression. A standard pressure-based microinjection approach presents greater reliability, precision, and overall control when delivering material to embryos, often preferred over electroporation in zebrafish studies...more

-

February 22, 2024

EVOM™ Auto, with both 24 and 96 HTS multiwell plate capability, is a high throughput screening (HTS) platform offering fast, noninvasive sample scanning by comparing electrical resistance measurements (transepithelial/transendothelial electrical resistance: TEER). TEER measurement experiments are simple to set up and less time consuming than more complex molecular studies. TEER measurement can be used as the primary scanning method to identify any physiological changes that can then be further evaluated by other methods. EVOM™ Auto can capture TEER measurements in 24 and 96 HTS multiwell plates from Corning, Millipore, or MatTek. The sample preparation time in these HTS plates is efficient, allowing for fast, multi-channel pipetting options.

The EVOM™ Auto autosampler ships with a red electrode array lock in place to prevent the electrode array connection port from moving during transit. Here you can see how to easily remove it without damaging the lock or the autosampler...more

-

February 19, 2024

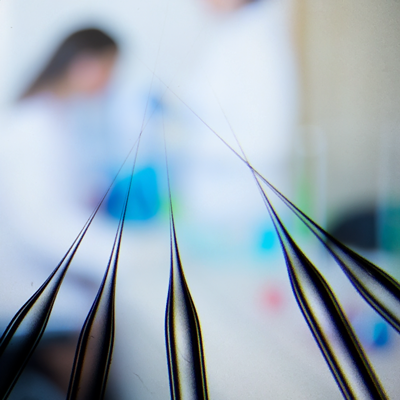

Below are some popular pullers from WPI, including Sutter pullers. Here we compare them so you can choose a system that is best suited for your application...more

-

February 02, 2024

Choosing a dependable lab equipment supplier is crucial for ensuring the quality, reliability, and timely delivery of the equipment you require. When your research is on the line, you need a company you trust, a supplier with a proven track record and a service team to back you up. Here are a few important considerations when selecting a lab equipment supplier...more

-

December 18, 2023Keeping your fine surgical scissors sharp is paramount for ensuring clean, efficient cuts. The precision of surgical cuts is crucial to the quick recovery of your subject and for minimizing the chance of infections. These tips will help keep your surgical scissors sharp and ensure a longer life for your instruments...more

-

December 08, 2023Leakages of your syringe can be extremely detrimental to the success of your fluid administration and overall application quality. Listed here are seven cases showing why your syringe might experiencing leakage, and how to overcome this...more

-

December 07, 2023Microfluidics is an ever-expanding practice involving fine-tuned control of ultra-low volumes of fluid, generally within the nanoliter to microliter scale. This area of study has considerably shifted approaches to scientific and industrial discovery. Particularly, utilizing a microfluidics-based approach in the realm of drug development has shown great promise in catalyzing movement to clinical trials by allowing for biological processes to be studied ex vivo, using more relevant human tissue models. Listed are just some of the means by which microfluidics is improving drug development processes...more

-

November 20, 2023Micromanipulators are widely used in cell biology, neurobiology, microelectronics, and microsurgery. Micromanipulators enable researchers to perform intricate tasks with high accuracy and stability, making them indispensable laboratory tools in a variety of applications...more

-

November 13, 2023

Let’s take a look at how to set up a Digital Rat/Mouse, Neonatal Rat Stereotaxic frame. In a few steps you will be up and running...more

-

November 08, 2023

Transepithelial/transendothelial electrical resistance (TEER) measurement is one of the most used practices to evaluate cellular health, such as cellular confluence, barrier integrity, or barrier function of cellular monolayers grown onto multiwells. The TEER measurement using WPI’s Epithelial Voltohmmeter (EVOM) is considered the gold standard because of its reliable measurements and numerous literature citations using various cell types. The EVOM™ Manual and EVOM™ Auto along with different choices of electrodes (STX4, STX HTS high throughput screening, EndOhm chambers, and multielectrode array for EVOM™ Auto) allow researchers to perform and analyze cell samples in 6, 12, and 24 removable inserts and 24 and 96 HTS multiwell plate formats. The major challenges researchers may encounter while performing studies to capture TEER measurement include:

· Unstable read outs

· Out of range values

· Inconsistent measurements...more -

November 06, 2023

Transepithelial Electrical Resistance (TEER) is a widely used technique in the life sciences fields and therapeutic development. It measures the electrical resistance across a cell monolayer, providing information about the integrity and functionality of epithelial barriers. TEER has proven to be a valuable tool in various fields, including drug absorption studies, tissue engineering, and disease modeling. This article aims to explore the benefits of TEER and its applications in different research areas...more

-

November 03, 2023

EVOM™ Auto High Throughput (HTS) Transepithiel Electrical Resistance (TEER) Measurement System with 24 and 96 transwell capability can switch between different 24 and 96 HTS well plates by using matching electrode arrays and plate positioners. Here we demonstrate how to switch to a 24 transwell plate after using a 96 transwell plate. ...more

-

November 02, 2023

EVOM™ Auto is WPI’s latest high throughput screening TEER measurement system with 24 and 96 HTS transwell plate measurement capability, and it offers easy options for switching between different plates. I will show you how to setup it up. The Interface Unit is the controller that establishes communication between the EVOM™ Auto software and the autosampler. ...more

-

October 31, 2023

EVOM™ Auto High Throughput (HTS) Transepithiel Electrical Resistance (TEER) Measurement System with 24 and 96 transwell capability can switch between different 24 and 96 HTS transwell plates by using matching electrode arrays and plate positioner. Here we demonstrate how to install a well plate. ...more

-

October 26, 2023

The EVOM™ Auto High Throughput (HTS) Transepithiel Electrical Resistance (TEER) Measurement System with 24 and 96 transwell capability has a removable electrode array head. Different electrode arrays can be used with the same system to analyze a variety of 24 and 96 transwell HTS plates. ...more