This website uses cookies to ensure you get the best experience on our website.

Read more

Factors that Affect the Pulling of Micropipette Glass Capillaries

April 21, 2022

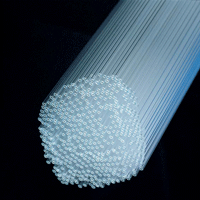

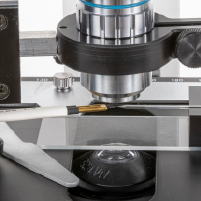

A PUL-1000 is a micro-processor controlled, four stage horizontal puller that is used for making glass pipettes and microelectrodes. This article defines several factors that affect the pulling of micropipette glass capillaries.

The glass transition is the gradual and reversible transition from a hard and relatively brittle solid state into a soft and viscous state as the temperature increases. To form glass into certain shapes using a puller, heat is applied through a filament.

Methods to Transfer Heat:

There are three methods to transfer heat:

- Direct conduction in solids

- Convection of air

- Radiation through anything that will allow radiation to pass.

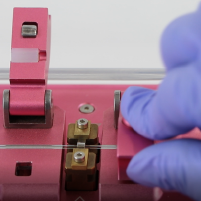

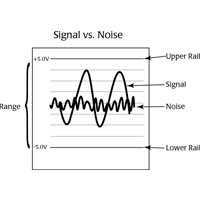

Many factors affect the heat transferred from a filament to a glass capillary. The filament holders are heated up when current passes through the filament. Also the heat from the surface of filament is conducted to filament holders. So, as the puller use continues, the temperate of filament holders increases. To reduce the heat residue built-up both in the filament and the filament holders, it takes time for the colder ambient air to cool the filament and the filament holders.

The convection of air in the ambient environment (both inside and outside of the cover chamber) affects the heat transfer from the filament to the glass. So, room temperature and humidity (in other word, density) affect the glass transition.

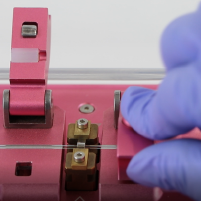

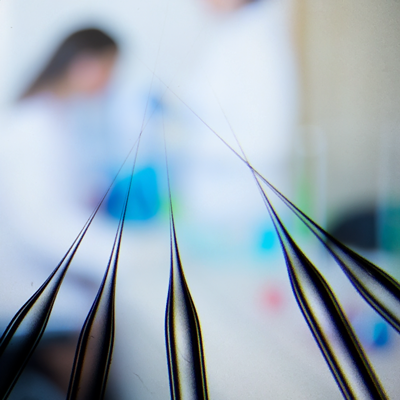

The heat radiating from the filament to the glass play the most important role in the glass transition. The distance between the surface of the glass and the surface of the filament depends on the amount of heat transferred. That is the reason why it is important to make sure the glass is placed at the center of the filament. All facets of glass should be heated evenly.

The filament is made of a platinum/iridium alloy. Even though platinum/iridium alloy is one of the most inert substances in the heating material market, it is still slowly oxidized by the oxygen from air. The mass of platinum/iridium alloy is reduced as the puller is used. It will eventually burn out. Thus, the temperature changes constantly.

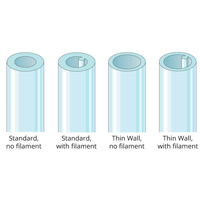

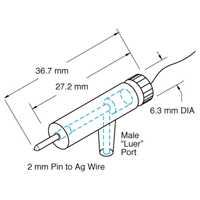

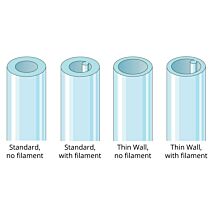

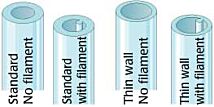

Different glass capillaries with different outside diameters (OD) vary in their glass softening points/temperatures. Variations of glass constituents among different glass capillary products show variations in their softening points. And, there is some variation of softening points of same glass capillary products taken from different lots. Some of our glass capillary product pulling sequences and results are shown above. You may need to make some fine adjusts of the pulling sequence parameters based on the glass capillary product you use and your laboratory environmental conditions (temperature and humidity).

As a rule of thumb, the parameters (Heat, Force, Distance, and Delay) can be altered accordingly to achieve desired shapes and dimensions of pre-pulled pipettes.

The table below shows basic guidelines for setting up a sequence.

| Parameter | Increase | Decrease |

| Heat | Longer Taper | Shorter Taper |

| Force | Smaller Tips, Longer Taper | Larger Tips, Shorter Taper |

| Distance | Smaller Tips | Larger Tips |

| Delay | Shorter Taper | Longer taper |

Close