This website uses cookies to ensure you get the best experience on our website.

Read more

VIDEO: Digital Microforge: Setting up the Microscope and Filament

January 17, 2022

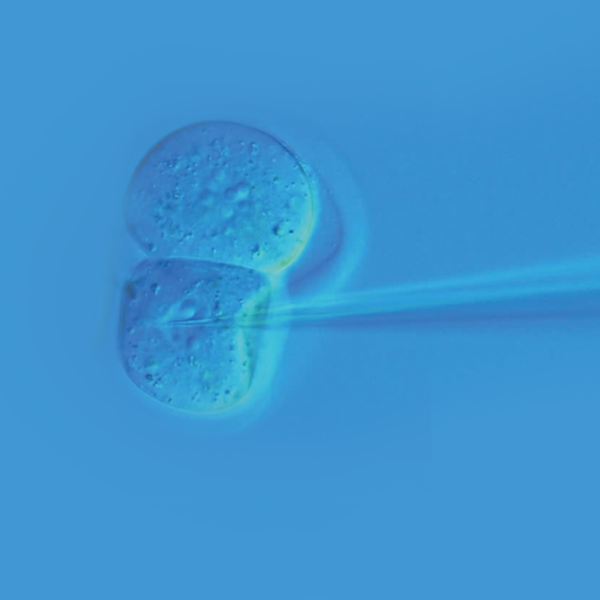

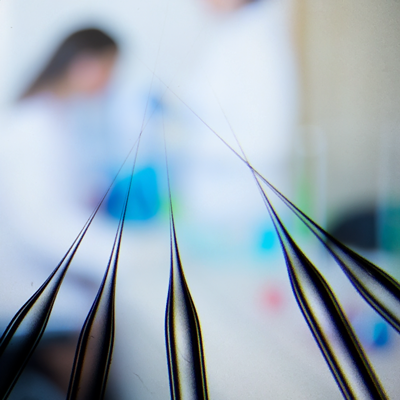

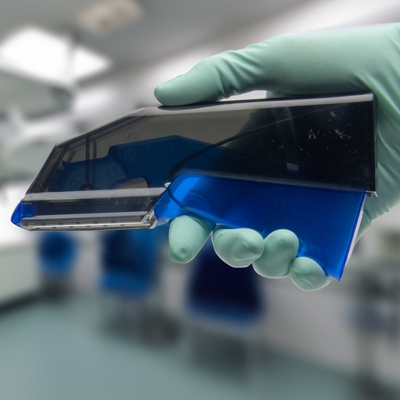

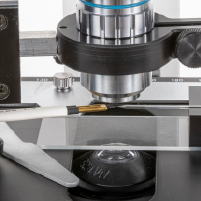

The DMF1000 is a microprocessor-controlled microforge designed for fabrication of both small patch clamp glass pipettes and larger injection pipettes. The DMF1000 can be used for polishing patch clamp pipettes, microforging holding pipettes, microforging beveled injection pipettes, and for calibrating pipette tips for microinjection. Here we will show you how to install the microforge filament on your microscope.

- After you turn on the power to the microscope, you must choose the desired filament.

- The small filament MF200-H4 is better suited for microforging pipettes 1 µm or less.

- The large filament DMF1000-H5 should be used for larger pipette forging, forming and sizing.

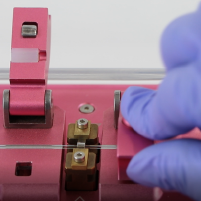

- Mount and connect the heating filament. Push the filament into the clamp about halfway, with the filament under the objective clamp. You can adjust the position of the filament vertically and laterally in relation to the objective.

- Lower the stage all the way and mount the filament holder on the objective. Slide the objective ring clamp of the filament holder over the 10× objective and tighten the thumb screw to secure it.

- Without using the microscope, adjust the position of the filament by moving it in or out and side to side until the filament wire is centered approximately 3 mm below the objective.

- Looking through the microscope, move the filament in the filament clamp until its shadow appears. Some vertical adjustment may also be required to bring the shadow into the field.

- Using the vertical adjustment knob, bring the filament into clearer view. With the horizontal adjustment knob, position the end loop of the filament to the far-right side of the visual field.

- Mount the pipette in its holder. Slide it in the groove and tighten the thumb screw.

- Then, install the slide on the stage. Position it so that it is focused in the field of view close to the filament, but far enough from the tip of the micropipette that the filament’s expansion will not allow it to touch the tip.

If you have any questions, call us at (866) 606-1974 or email [email protected].

Close