This website uses cookies to ensure you get the best experience on our website.

Read more

Micromanipulator Basics

November 20, 2023

Micromanipulator Basics

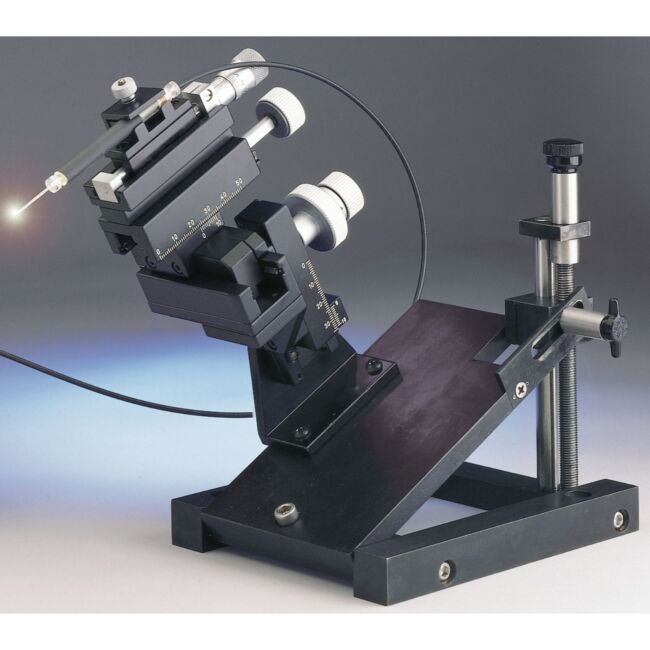

Micromanipulators are a common laboratory instrument for precise, controlled manipulation of microscopic objects such as cells, tissues, small organisms, and delicate structures. They are widely used in cell biology, neurobiology, microelectronics, and microsurgery. Micromanipulators enable researchers to perform intricate tasks with high accuracy and stability, making them indispensable laboratory tools in a variety of applications. Here's an overview of micromanipulators used in a lab.

Applications of Micromanipulators

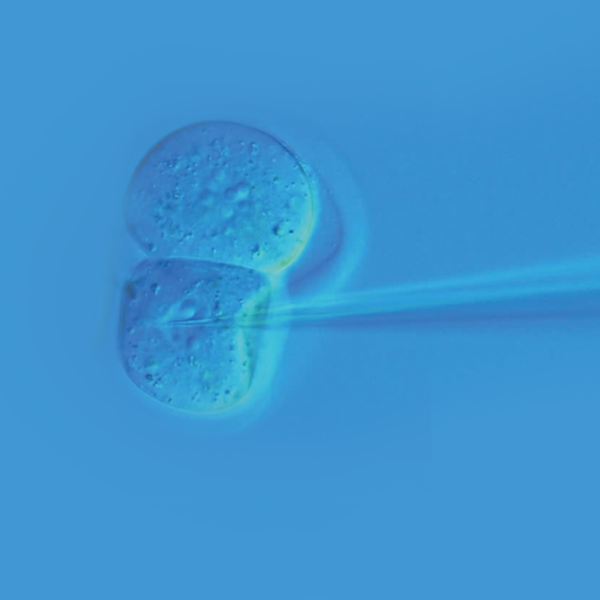

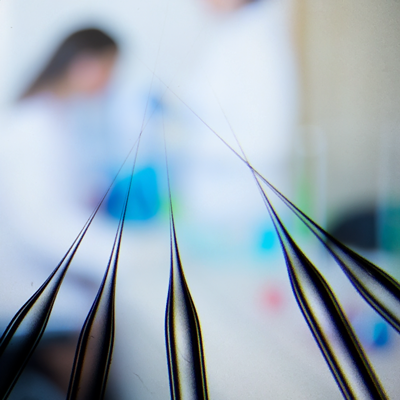

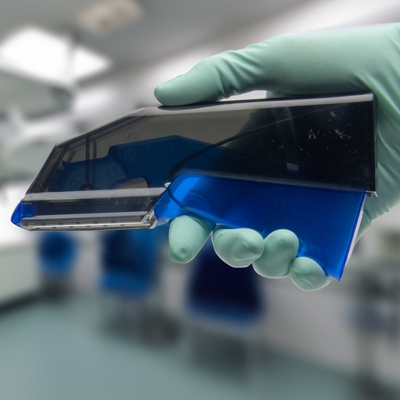

Micromanipulators are used to inject substances, such as genetic material or dyes, into individual cells. They are frequently used in electrophysiology experiments to create a high-resistance seal between a micropipette and a cell membrane for studying ion channels. Researchers use micromanipulators to position electrodes inside cells to record electrical activity and study cellular functions. For delicate surgical procedures on small organisms, such as dissecting embryos or performing neural surgery on small animals, a micromanipulator is invaluable. And,they enable the manipulation of cells for studies involving cell signaling, migration, and interactions.

Micromanipulators play a crucial role in advancing our understanding of biological processes and enabling precise experimentation in various scientific fields. Their ability to provide fine control over microscopic objects contributes to breakthroughs in research and technology development.

Components of a Micromanipulator

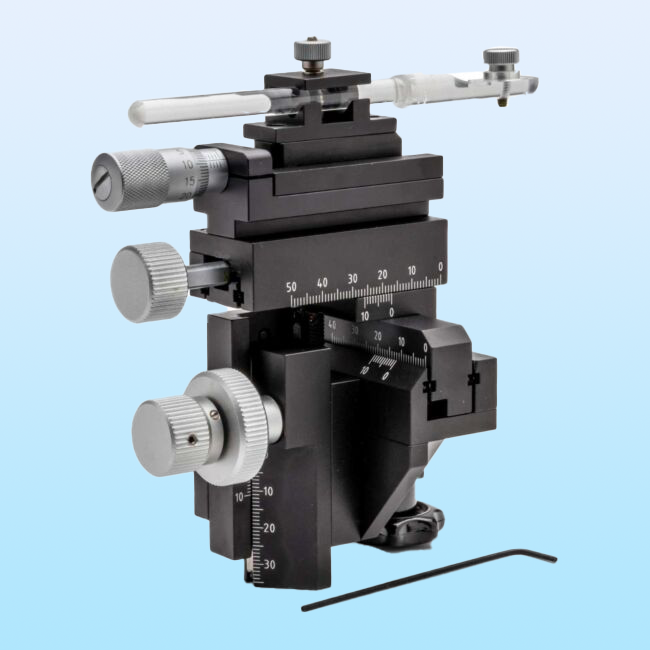

These basic components are part of every micromanipulator:

- Manipulator stand is the base and frame that provide stability and support for the manipulator's components.

- Micropipette holders secure the micropipettes, needles, or electrodes used for manipulation. They allow fine adjustments to be made in three dimensions.

• Control knobs allow researchers to make minute adjustments to the position of the micropipette or electrode. - Translation controls enable movement of the micropipette or electrode along one or more of the X, Y, and Z axes for precise positioning.

- Coarse/fine movement controls allow for rapid and precise positioning. Coarse adjustment allows for approximate positioning and fine adjustment for accurate positioning.

- Stabilization mechanisms of some micromanipulators insulate the micropipette or electrode against vibrations, which is crucial for delicate procedures.

Tips for Maintaining Your Manipulator

Maintaining micromanipulators in good working order is essential to ensure accurate and reliable results in your laboratory work. Here are some tips for proper care and maintenance.

Cleaning

- Keep your micromanipulators clean and free from dust, debris, and residue. Wipe down surfaces with a clean, lint-free cloth and use a gentle cleaner when necessary. Wipe up any spilled liquids immediately.

- Follow the manufacturer's guidelines for lubricating moving parts, if required. Note that too much lubrication can attract dust and debris. Use recommended lubricants sparingly.

Handling

- Handle micromanipulators with care. Avoid sudden impacts or jerky movements that could damage delicate components or throw off the calibration.

- Do not drop your micromanipulator.

Usage

- Do not overload your micromanipulators beyond their recommended weight capacity. Excessive force can damage mechanisms and compromise accuracy.

- Use accessories and replacement parts that are recommended by the manufacturer to ensure compatibility and proper functioning.

Location & Storage

- Place your micromanipulators on stable surfaces and use anti-vibration equipment if your lab is prone to vibrations. Vibrations can disrupt delicate manipulations.

- Store your unused micromanipulators in a clean and dry environment. Cover or protect them to prevent dust accumulation.

Calibration, Inspection & Documentation

- Regularly calibrate and align your micromanipulators according to the manufacturer's instructions. Proper alignment ensures accurate and precise manipulation.

- Regularly inspect your micromanipulators for worn or damaged parts. Replace any worn components, such as knobs, holders, or cables.

- Establish a schedule for routine maintenance checks. This could involve a visual inspection, a functional test, and any necessary adjustments.

- Keep a record of maintenance activities, calibration dates, and any issues encountered. This record helps ensure consistent performance and troubleshooting.

- Always follow the manufacturer's maintenance recommendations and guidelines provided in the user manual.

Motorized Manipulator Tips

- When you use motorized micromanipulators with electronic components, ensure proper electrical safety. Use surge protectors and avoid exposing them to liquids.

- Ensure that cables are properly managed and do not impede movement or get tangled. Cable strain can affect performance and safety.

Micromanipulators are indispensable in a lab. Having a basic understanding of the components of your manipulator will get you up and running quickly. Armed with some introductory information you can improve your microinjection results. By following these maintenance practices, you can lengthen the usable life of your laboratory equipment, ensure accurate manipulations, and maintain the reliability of your experimental results.

If you have an questions, just give us a call at (866) 606-1974 or email us at [email protected].

Close