This website uses cookies to ensure you get the best experience on our website.

Read more

How Microfluidics is Changing Drug Development

December 07, 2023

How Fluidics is Changing Drug Development

Microfluidics is an ever-expanding practice involving fine-tuned control of ultra-low volumes of fluid, generally within the nanoliter to microliter scale. This area of study has considerably shifted approaches to scientific and industrial discovery. Particularly, utilizing a microfluidics-based approach in the realm of drug development has shown great promise in catalyzing movement to clinical trials by allowing for biological processes to be studied ex vivo, using more relevant human tissue models. Listed are just some of the means by which microfluidics is improving drug development processes.

Models

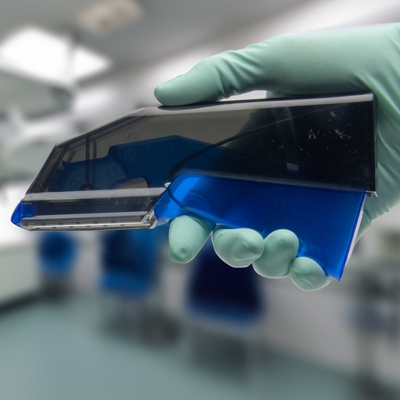

Organ-on-a-Chip Technology

Microfluidic chips, particularly organ-on-a-chip models, facilitate the study of tissues or organoid systems at the microscale range in real-time. Isolating certain structures in this way allows for improved focus of the structure of interest, an ultra-localized approach to observing drug interactions and toxicity at a specific area of the biological system. The chip-based approach offers an improved methodology of emulating physiological conditions compared to traditional methods, such as utilizing animal models or looking at whole-scale cell cultures.

Lab-on-a-Chip Technology

Similar to the idea of Organ-on-a-Chip technology, Lab-on-a-Chip combines several systems either on a single chip, or through a multi-chip system. While this approach is much more challenging, the ability to expand the range of system observation accelerates the application timeline and allows for the investigation of downstream processes when introducing a drug, altering the electrical field, and much more.

Precision Medicine and Tailor-Made Therapies

Implementing the microfluidic approach offers an adaptive means of paralleling certain physiological conditions specific to an individual patient. This supports researchers in their efforts to conduct studies using smaller sample sizes (reducing R&D costs) while accelerating the advancement of personalized medicine and treatments.

Further, microfluidic devices facilitate the isolation and research of rare cells, such as circulating tumor cells, which can reveal important information as to the disease development process and appropriate treatments.

High-Throughput Screening (HTS)

Using microfluidic platforms assists in streamlining experimentation and the screening of several drug variants simultaneously. The compactness of microfluidic chips decreases reagent consumption, promoting cost effectiveness as well as facilitating bulk testing of drug candidates.

Continuous Manufacturing

The implementation of microfluidics and microfluidic chips promotes uninterrupted drug processing and production for pharmaceuticals. Where batch production implies incremental processing and testing across numerous discrete stages, continuous manufacturing fuses the full manufacturing process into one, fully cohesive workflow. Continuous production removes built-in production gaps and can cut down manufacturing times from months to days, ultimately resulting in significant end-to-end cost savings, as well as enhanced drug quality.

Nanoparticle Drug Delivery Systems

Previously tedious and time-consuming methods to study nanoparticle-based interactions have been simplified utilizing microfluidics and the associated chip platforms. The microfluidics approach can be used to create nanoparticles with a defined size, shape, and surface properties. The fine-tuned control of nanoparticle manipulation improves drug delivery and efficacy, while permitting side-effect evaluation prior to introduction to a patient.

Biosensing and Diagnostics

To add to the vast list of benefits microfluidic devices offer, this technology can be implemented in the development of biosensors. The benefit of improving biosensing allows for increased sensitivity to micro-reactions in a system for more accurate point-of-care diagnostics.

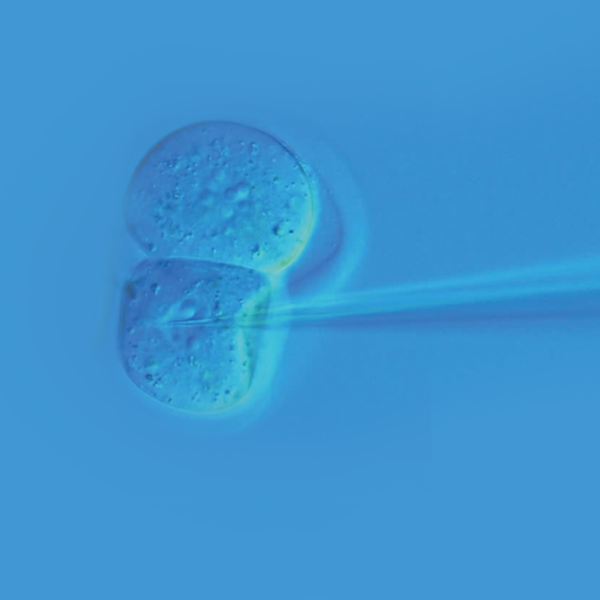

Cell Culture and Tissue Engineering

Utilizing microfluidic channels or reservoirs within the small chip platforms, microfluidics provides a controlled environment for cell culture and tissue manufacturing studies. This provides researchers with the ability to construct complicated 3D structures and investigate cell activity under dynamic conditions, simulating an in vivo setting.

Drug Formulation and Optimization

Implementing microfluidics processing creates greater control over the combining and construction of drug compounds, accelerating the development of improved drug bioavailability and stability.

Overall, microfluidics is transforming drug development by affording groundbreaking solutions for organ- and lab-on-a-chip models, and tailor-made therapies. It is allowing for personalizing medicine, improving manufacturing and lowering production costs, improving speed of study with high-throughput screening methodologies, and much more to come. The advancements being made in microfluidic-based research significantly catalyzes the road to drug discovery, optimization, and delivery processes. WPI's microinjection pumps and UMP3 syringe pump are popular for microflluidic applications.

If you have an questions, just give us a call at (866) 606-1974 or email us at [email protected].

Close