This website uses cookies to ensure you get the best experience on our website.

Read more

Surgical Instrument Coatings and Features

June 19, 2015

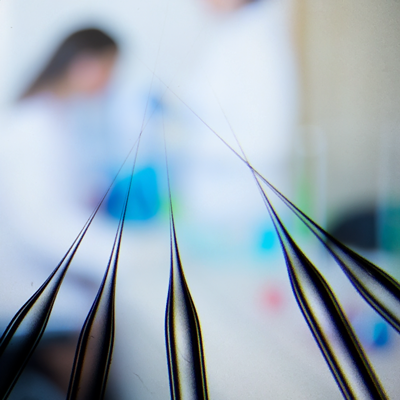

Surgical instruments for dissecting come in a variety of patterns, types, shapes and sizes. Choosing the correct one for your application will improve outcome and reduce the frustration of trying to use an inappropriate tool.

Choosing a Set of Forceps

Ceramic Forceps

Ceramic contains no metal. So, ceramic forceps will not leave any trace metal residue on tissue. This is especially useful in forensic science research. Ceramic is not electrically conductive, so it can be used for handling gels in an electrophoresis bath. Ceramic's corrosion resistance allows its use in highly corrosive solutions. For example, it could be used to clean quartz cover glass or lithographic produced chip sensors in an acid solution without damaging the forceps. Ceramic's low heat conductivity and high heat resistance allow it to hold parts in a flame for sterilizing or fabricating. Although the flame with eventually reduce the strength of the ceramic tip, it will be minimal.

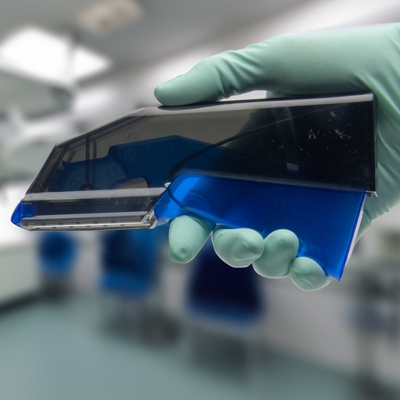

Titanium Forceps

Titanium is 100% non-corrosive (great for seawater procedures), non-magnetic (perfect for MRI) and has a heat resistance to 550°C. Titanium is 40% lighter ![]() than stainless steel (reduces hand fatigue) and has an anodized, non-glare, blue finish. Titanium forceps are coated with tungsten carbide for increased gripping power and are more flexible than stainless steel forceps, therefore the tips are more likely to bend under pressure than break.

than stainless steel (reduces hand fatigue) and has an anodized, non-glare, blue finish. Titanium forceps are coated with tungsten carbide for increased gripping power and are more flexible than stainless steel forceps, therefore the tips are more likely to bend under pressure than break.

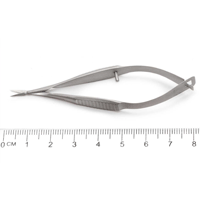

Round-Handled Forceps

By hollowing out the handles of long, round-handled surgical instruments, the overall weight is decreased. This makes them efficient and non-fatiguing when operating under a microscope. Made from high quality stainless steel, these instruments are an excellent addition to a micro-surgical instrument kit.

Choosing Scissors

Ceramic Coated Scissors

Coating surgical instruments with a black ceramic offers several distinct advantages. First, the coating adds a thin layer to the metal instrument that actually makes the instrument harder, offering surgeons greater precision and perfection. This anti-glare surface minimizes any reflection off the surface of the instrument. In addition, the ceramic coating is incredibly smooth, which improves the instruments resistance to corrosion. The smooth surface also minimizes friction. The reduced wear and tear means coated instruments last considerably longer. It is nearly impossible to penetrate the ceramic coating, because the raw material is bonded to the instrument both physically and chemically. The black coated instruments are much more resilient to the pressure of daily use and chemical processing.

SuperCut Scissors

There are scissors that have the option of one edge being micro serrated, and the other edge having the sharpness of a knife-edge. This option is provided in a number of scissor types and models. WPI designates this option with a black handle.

in a number of scissor types and models. WPI designates this option with a black handle.

SuperCut Tungsten Carbide

Scissors combine the precise cutting action of the razor-sharp SuperCut blades with the durability of Tungsten Carbide. They provide a clean, smooth cut and retain their sharpness for an extended period of time.

Close