This website uses cookies to ensure you get the best experience on our website.

Read more

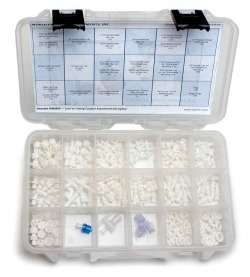

Sterilizing Plastic Parts and Pieces

April 25, 2013

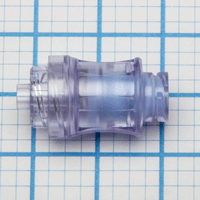

Luer kits contain many plastic parts made of a variety of materials. A common question is how to sterilize these parts. Common sterilizing methods include:

Luer kits contain many plastic parts made of a variety of materials. A common question is how to sterilize these parts. Common sterilizing methods include:

- EtO (gas)–a chemical steriliant small enough to penetrate the microbial cells that destroying nuclear cell components

- 70/30 Alcohol

- Cidex (Activated Dialdehyde solution)

- Autoclaving (wet 121°C, 15PSI for 30 minutes)–Before autoclaving, verify that the caps are properly loosened or removed to prevent any accidental implosion. Carefully clean the items with distilled water before autoclaving, because some chemicals that are inert on plastic resins at room temperature causes deterioration at high temperatures.

Can the Luer Kits be Autoclaved?

We offer to following luer kits. This table shows the materials used in each kit and whether or not the plastic parts are autoclavable.

| Order code | Materials |

Autoclavable |

| 504955 | Nylon | NO |

| 504954 |

Polypropylene | Yes |

| 14011 |

Variety | Some pieces can be |

What Materials are Autoclavable?

This table shows a variety of materials and offers general guidelines for sterilizing parts manufactured from these materials.

| Material |

Autoclave |

Max Temp |

Brittle Temp |

Appearance |

Notes |

| Acrylic (PMMA) | no | 50°C | 20°C | Clear | Alcohol causes crazing and weakening |

| Fluoroelastomer Tubing (LPF) | yes* | *Once on a wet cycle | |||

| HDPE | no | 120°C | -100°C | Translucent | High density polyethylene |

| LPDE | no | 80°C | -100°C | Translucent | Low density polyethylene |

| Nylon | no | ||||

| PFA | yes | Can be autoclaved repeatedly at 121°C/15PSI, 15 min. cycles | |||

| Polyacetal | yes | Can be sterilized by EtO, steam and autoclave, but degrades under high energy radiation. | |||

| Polycarbonate (PC) | yes | 135°C | -135°C | Transparent | Weakened by repeated autoclaving, and may not perform well in high stress applications like centrifuges. Rinse thoroughly before autoclaving, because detergent residues cause crazing and spotting. No more than 20min. at 121°C. |

| Polyester | no | Glass transition 80-85°C | |||

| Polyethylene (HPP) or HPP Tubing | no | ||||

| Polymethylpentene | yes | Can be autoclaved repeatedly at 121°C/15PSI, 15 min. cycles | |||

| Polypropylene | yes | 135°C | 0°C | Translucent | Can be autoclaved repeatedly at 121°C/15PSI, 15 min. cycles |

| Polypropylene copolymer | yes | Can be autoclaved repeatedly at 121°C/15PSI, 15 min. cycles | |||

| Polystyrene (PS) | no | 90°C | -40°C | Clear | |

| Polysulfone (PSF) | yes | Weakened by repeated autoclaving | |||

| Polyurethane or Polyurethane tubing | no | This tubing is used in kit 500890 | |||

| Polyvinyl Chloride (PVC) | no | 70°C | -30°C | Clear | |

| PTFE (Teflon) or Teflon Tubing | yes | 260°C | -100°C | Opaque | Can be repeatedly autoclaved. Do not run fluid through the tubing after autoclaving until the tubing has cooled to room temperature. |

| Silicone | yes | ||||

| Silicone tubing | yes* | *Once on a wet cycle (PeriStar Pro tubing) | |||

| Vinyl tubing | no | 70°C | -30°C | Clear | No organic solvents |

| Viton | yes |

Close