This website uses cookies to ensure you get the best experience on our website.

Read more

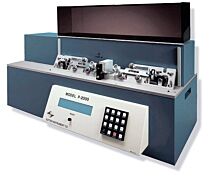

PULLER, PIPETTE, 4-STEP

$5,184.00

Prices valid in USA, Canada, and PR only.

Order code

PUL-1000

Prices valid in USA, Canada, and PR only.

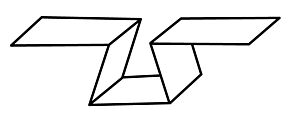

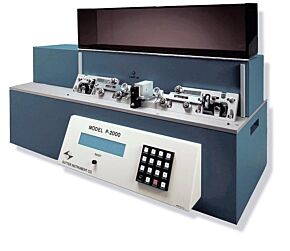

PUL-1000 is a microprocessor controlled horizontal puller for making glass micropipettes or microelectrodes used in intracellular recording, patch clamp studies, microperfusion or microinjection. The puller was designed with tight mechanical specifications and precision electronics for complete control of the pulling process and accurate reproducibility. It offers programmable sequences of up to four steps with heating, force, movement and cooling time. This allows graduated cycles for applications like patch clamp recording.

Prices valid in USA, Canada, and PR only.

A compact, versatile and reliable workhorse

Features

Program sequences up to four steps

Program sequences up to four steps- Produce micropipettes with a tip diameter less than 0.1 µm or greater than 10 µm

- Store up to 95 programs in memory for easy recall

- Two factory programs installed

- Includes:

- (1) PUL-1000 Puller

- (2) Glass clamp pads for 1.0~1.2 mm OD glass (translucent, pre-installed as default)

- (2) Glass clamp pads for 1.0~1.2 mm OD glass (translucent, spares)

- (2) Glass clamp pads for 1.5 mm OD glass (black)

- (2) Glass clamp pads for 2.0 mm OD glass (red)

- (1) Power supply

See the current Data Sheet.

Benefits

- Tempered glass cover to reduce the effects of humidity on puller reproducibility

- Switchable power supply for any line voltage 90–240 VAC ensures that line voltage fluctuations don’t affect reproducibility

Applications

- Pull your own microelectrodes and micropipettes

PUL-1000 is a microprocessor controlled horizontal puller for making glass micropipettes or microelectrodes used in intracellular recording, patch clamp studies, microperfusion or microinjection. The puller was designed with tight mechanical specifications and precision electronics for complete control of the pulling process and accurate reproducibility. It offers programmable sequences of up to four steps with heating, force, movement and cooling time. This allows graduated cycles for applications like patch clamp recording.

This puller is a reasonably priced, compact, versatile and reliable workhorse. The microprocessor, combined with the LCD display, makes the PUL-1000 easy to use.Tempered glass cover

The cover of the pulling chamber is made with tempered glass to minimize the temperature effect on the reproducibility of the pulled pipettes.

Switchable power supply

PUL-1000 has a high quality switching power supply for use anywhere in the world without worry about the line voltage differences. Pulling reproducibility is unaffected by line voltage fluctuation. Heating voltage can be controlled to within 0.1% accuracy even when line voltage fluctuates from 90 to 240 VAC.

Programming

The settings for both stages can be stored in memory. Up to 95 user-selectable programs can be stored for later recall. The instrument contains two factory installed and tested programs. Choose from the factory installed programs or create your own.

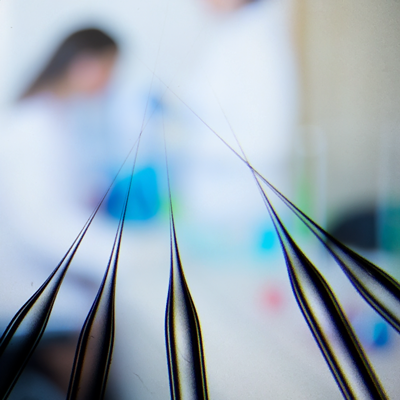

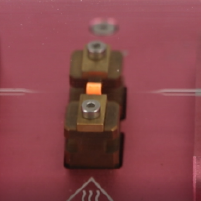

Pulling glass

A glass capillary is heated by a platinum/iridium filament and pulled by a controlled force. PUL-1000 features permanent memory storage for up to 95 heat programs. It is remarkable in the flexibility and capability of producing a vast array of pipette shapes.

Pulling pipettes is an art, and reliable results depend on factors like the operating environment, the type of glass used and your technique. Understanding how the puller works is critical to manufacturing the pipettes you want.

PUL-1000 can produce pipettes with tip diameters from less than 0.1µm to 10+ µm. Microprocessor settings control the pulling automatically.

Choosing a Filament

Appropriate filament selection depends on your research application, but generally Box Filaments are recommended. This configuration is particularly suitable for slice preparations where long, parallel walls will aid penetration. If you are using a box filament, the size of the square box should be approximately 1.0mm to 1.5mm larger than the outside diameter of the glass to be pulled.

| Order code | Description |

| 13834 | Replacement box filament, 2.5 mm square, platinum iridium, 2.5 mm wide (Installed by default) |

| 14074 | Replacement box filament, 3 mm square, platinum iridium, 2 mm wide |

More Information

Compare all the pullers, bevelers, microforges (application guide).

| SKU | PUL-1000 |

|---|

Upsell Products

-

Box Filament for Micropipette Pullers

As low as $92.00

PUL-1000 Programmable Puller Instruction Manual

Video

Getting Started with your PUL-1000 Micropipette Puller

How to Load Capillary Glass in a PUL-1000 Micropipette Puller

How to Run a Glass Softening Test on the PUL-1000 Puller

Resolving Common Issues with the PUL-1000 Puller

How to Load a Program to Pull Glass Using the WPI PUL-1000

How to Create a Program to Pull a Glass Micropipette with the WPI PUL-1000

How to Modify an Existing Program in the WPI PUL-1000 Micropipette Puller

The video below gives a brief overview of this microelectrode/micropipette puller and its features.

Five Factors Affecting the Pulling of Glass Micropipettes

Why Buy a PUL-1000 Research Puller for Making Micropipettes?

Get Familiar with Your PUL-1000 Glass Puller

| Type | Description |

| Heater Element | Platinum/Iridium Filament |

| Pulling Force | Solenoid, adjustable |

| Taper Length | 1–10 mm |

| Capillary OD Range | 1.0–2.0 mm* |

| Maximum Capillary Length | 170 mm |

| Minimum Capillary Length | 55 mm |

| Permanent Memory Set | 95 (including 15 factory-installed programs) |

| Power | 90–240 VAC, 50/60 Hz, Max. 70 W |

| Replacement Filaments | 13834 2.5mm Square Box Filament, 2.5mm wide |

| DIMENSIONS | 34 x 24 x 12 cm (13.4 x 9.4 x 4.7") |

| WEIGHT | 15 lb. (7 kg) |

*Use the white pad (default) with 1-1.2 mm glass, the black pad with 1.5 mm glass and the red pad with 2 mm glass.

Dolat, L., & Valdivia, R. H. (2021). An endometrial organoid model of Chlamydia -epithelial and immune cell interactions . Journal of Cell Science, 134(5), jcs.252403. https://doi.org/10.1242/jcs.252403

Aljiboury, A. A., Mujcic, A., Cammerino, T., Rathbun, L. I., & Hehnly, H. (2021). Imaging the early zebrafish embryo centrosomes following injection of small-molecule inhibitors to understand spindle formation. STAR Protocols, 2(1), 100293. https://doi.org/10.1016/j.xpro.2020.100293

Holicki, C. M., Michel, F., Vasić, A., Fast, C., Eiden, M., Răileanu, C., … Ziegler, U. (2020). Pathogenicity of West Nile Virus Lineage 1 to German Poultry. Vaccines, 8(3), 507. https://doi.org/10.3390/vaccines8030507

Casey, G., Askew, C., Brimble, M. A., Samulski, R. J., Davidoff, A. M., Li, C., & Walters, B. J. (2020). Self-complementarity in adeno-associated virus enhances transduction and gene expression in mouse cochlear tissues. PLOS ONE, 15(11), e0242599. https://doi.org/10.1371/journal.pone.0242599

Chen, M., Liu, A., Chen, B., Zhu, D. M., Xie, W., Deng, F. F., … Wang, F. B. (2019). Erythrocyte-derived vesicles for circulating tumor cell capture and specific tumor imaging. Nanoscale, 11(25), 12388–12396. https://doi.org/10.1039/c9nr01805k

Lefky, C. S., Mamidanna, A., & Hildreth, O. J. (2018). Ultra near-field electrohydrodynamic cone-jet breakup of self-reducing silver inks. Journal of Electrostatics, 96, 85–89. https://doi.org/10.1016/j.elstat.2018.10.006

Plautz, C. Z., Williams, H. C., & Grainger, R. M. (2016). Functional Cloning Using a <em>Xenopus</em> Oocyte Expression System. Journal of Visualized Experiments, (107), e53518–e53518. https://doi.org/10.3791/53518

Komarova, Y., Peloquin, J., & Borisy, G. (2011). Components of a microinjection system. Cold Spring Harbor Protocols, 2011(8), 935–939. https://doi.org/10.1101/pdb.ip27