This website uses cookies to ensure you get the best experience on our website.

Read more

Electrodes

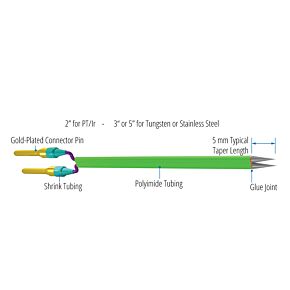

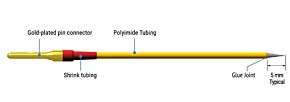

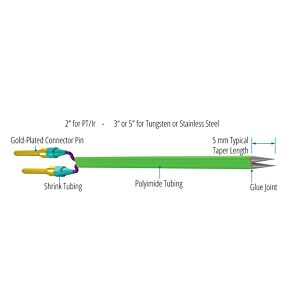

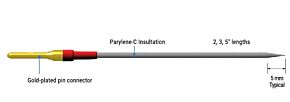

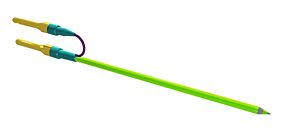

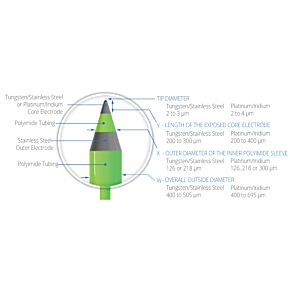

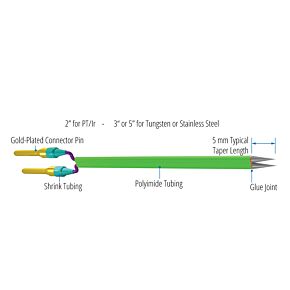

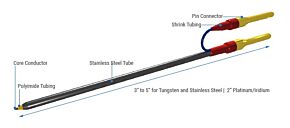

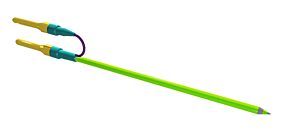

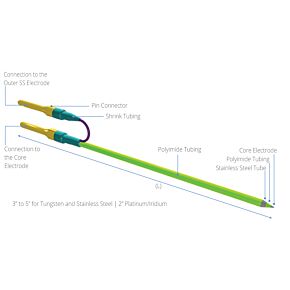

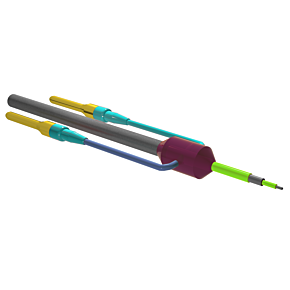

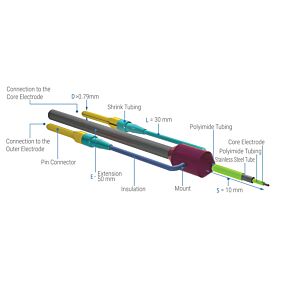

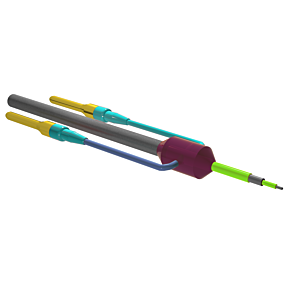

WPI electrodes are commonly used in electrophysiology and neuoroscience research. We off superior microelectrodes for outstanding extracellular recording in tungsten, iridium, platinum-iridium and Elgiloy® steel. These metal electrodes may be insulated with a thin film of vapor-deposited Parylene-C, and they come in 4different tip profiles (Standard, Heat treated, Blunt and Fine tips). They have a high corrosion resistance for consistent, long-term performance.

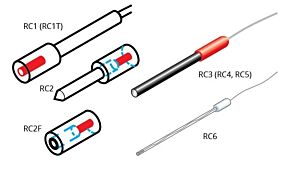

Dri-Ref™ reference electrodes were developed by WPI to have extremely low electrolyte leakage properties. These electrodes exhibit stable and reproducible potential and low resistance. Stored in KCl when not in use, they have a long life expectancy. Electrode resistance is low, an important consideration when making low-noise measurements.

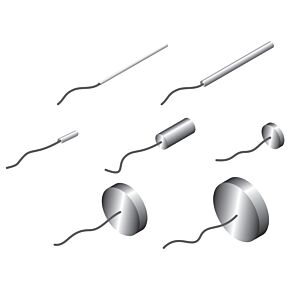

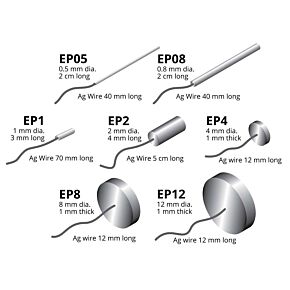

WPI's silver-silver chloride half cells are new, improved sintered pellets with lower resistance and high strength. They are stable and well-balanced in the presence of current. These small and inexpensive half-cells are easy to work with as bath electrodes.

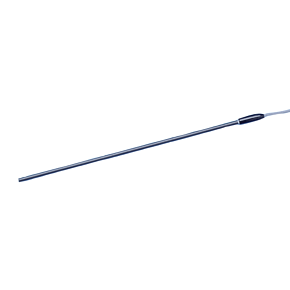

Pre-pulled, calibrated micropipettes save you time. With MicroTips, you get consistently sized pre-pulled glass micropipettes for injection of dyes or proteins into cells, oocytes and for many other biomedical laboratory applications.

- hiddenBack to TopClose