This website uses cookies to ensure you get the best experience on our website.

Read more

REMS High Throughput TEER Robot Gets Software Upgrade

May 30, 2014

What is REMS?

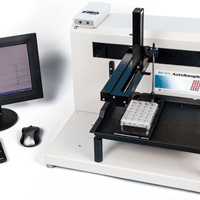

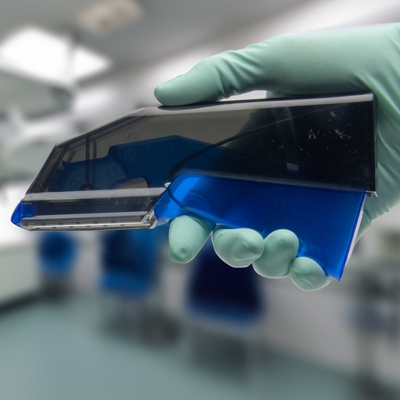

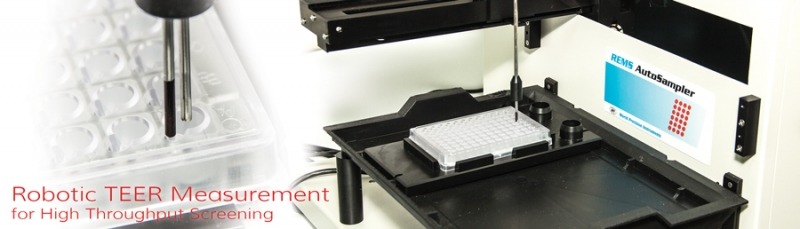

The REMS AutoSampler automates measurements of electrical resistance of transepithelial, transendothelial or Caco-2 cell membranes being grown to confluence on microporous filters of high throughput screening (HTS) 24- and 96-well microplates. It is a PC-controlled, tissue resistance measurement system that offers reproducibility, accuracy and flexibility for this kind of measurement. The ability of the REMS AutoSampler to precisely locate the electrode results in highly reproducible TEER measurements. TEER measurements are stored in the computer as the electrode moves from one well to the next. The Windows-based software provides user-friendly features to acquire, display and store the tissue resistance measurements.

Automated measurement of tissue resistance in cell culture microplates provides important advantages:

-

Drastically reduces time required to evaluate TEER on culture plates with HTS form factor

-

Superior repeatability relative to manually acquired measurements

-

Significantly reduces the potential for measurement error

-

Compatible with major manufacturers of HTS culture plates

-

Preconfigured at the factory to your choice of culture plate(s)

-

Data automatically saved as text files which are easily imported into Excel

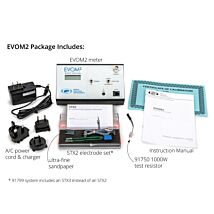

The REMS AutoSampler automates TEER measurements previously made with WPI’s EVOM2 Epithelial Voltohmmeter. Automated tissue resistance measurements up to 20kΩ can be performed on 24- or 96-well HTS microplates. The REMS AutoSampler is compatible with Corning Costar HTS Transwell-24 and 96-well plates, Millipore MultiscreenTM CaCo 96-well plates and BD Falcon 96- and 24-well plates.

The REMS AutoSampler automatically measures and records tissue resistance from a user-specified matrix of culture wells on the microplate. According to the specified sequence, the robotic arm moves into the identified wells taking TEER measurements. By means of a X-Y-Z locating system, the electrode arm is positioned precisely and reproducibly over each well.

What's New?

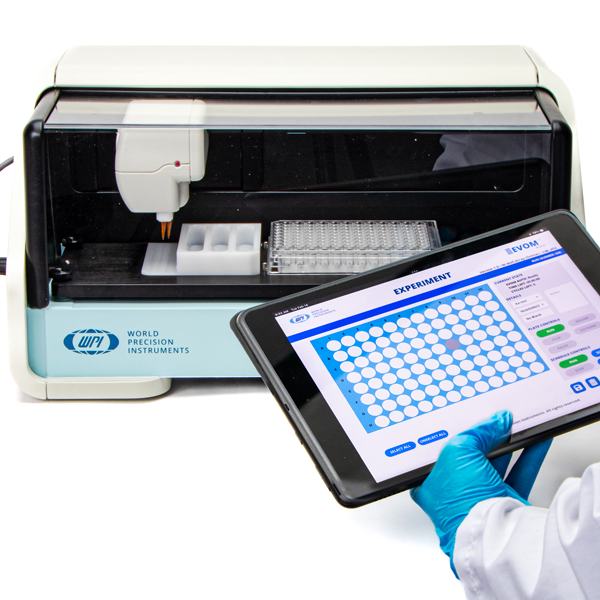

WPI just released a software upgrade for the REMS AutoSampler. The software runs on Windows 10. In addition to the operating system updates, the new software includes a host of new features, including:

- Dual rinse station locations and a calibration station location. The rinse station can be used to park the electrode while it is not in use. The system allows you to automate rinsing after each measurement, or you may pause the system at any time and rinse manually.

- Brand new interface that allows you to customize the name the background data files and the resistance data files from any tab.

- Safety features added to prevent damage to expensive probes.

- Simulation mode allows you to run the software without a robot connected. This works well for testing the software.

- Press the Stabilize button to see the resistance of the stabilizing well display on screen.

New REMS AutoSampler systems includes the computer with all the hardware and software installed, the REMS Interface Unit, the robotic arm, a dummy electrode and one measurement electrode of your choice.

PC Requirements

To upgrade an existing REMS system to this new version, your PC needs to meet these minimum requirements:

- Windows 10 compatible PC (64 bit)

- CPU dual core 3GHz

- RAM 2 GB

- One spare PCI slot

- RS232 port or a spare USB 2.0 connector (and a USB2.0- to RS232 convertor)

In addition, you will also require a new PCI-6220 National Instruments Data Acquisition card (Software upgrade + Card cables available as P/N 300555).

Close