This website uses cookies to ensure you get the best experience on our website.

Read more

Choosing a Pump for your Fluid Handling Application

October 04, 2015

The type of pump you choose for your fluid handling will largely depend on your laboratory application. In this article, we will compare the popular pump types.

Microinjectors

WPI Microinjectors use carefully regulated air pressure for injecting cells with fluid. Injected volumes range from picoliters to nanoliters. The port supplies positive pressure for high-pressure ejection. The pressure port maintains a low positive “compensation” pressure to the injecting pipette between injection pulses to prevent fluid uptake through capillary action.

Timing, injection pressure and compensation pressure are adjusted independently using the touch screen interface. Time intervals can range from 2 seconds down to 10 ms or less, depending on the injection pressure setting. The injection pressure interval is triggered by using a foot switch or a computer-controlled TTL pulse.

The WPI Microinjectors are designed to inject very small quantities of fluids, such as drugs, into cells or small organelles. Pressure injection is an especially useful alternative to electroionophoresis, since it does not mandate the use of charged ions. Two different positive pressures may be applied: one for ejection at high pressure and a second, lower pressure to prevent back filling of the pipette by capillary action.

The WPI Microinjectors offers separate regulated compensation (back filling prevention) and ejection pressures with a precision timing circuit that switches from injection pressure to compensation pressure automatically. We offer three different microinjectors to choose from based on your application.

- The MICRO-ePUMP has an internal pressure source and the integrated MICRO-ePORE™ Pinpoint Cell Penetrator technology.

- The uPUMP also has in internal pressure source.

- The PV850 microinjector requires an external pressure source.

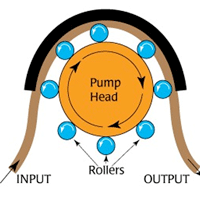

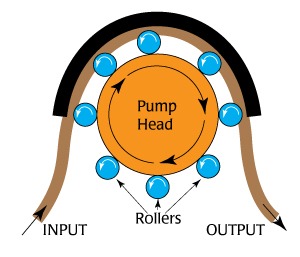

Peristaltic Pumps

A Peristaltic Pump has a series of rollers that rotate around the edge of the pump head. A flexible tubing is threaded around the rollers and pressed up tight next to them, pinching the tubing where it contacts a roller. As the rollers rotate around the head, the fluid in the tubing moves from the input to the output. The rate of head rotation and the size of the tubing determine the volume of fluid that can be pumped. The volume that can be pumped is limited only by the volume of the input source.

A Peristaltic Pump has a series of rollers that rotate around the edge of the pump head. A flexible tubing is threaded around the rollers and pressed up tight next to them, pinching the tubing where it contacts a roller. As the rollers rotate around the head, the fluid in the tubing moves from the input to the output. The rate of head rotation and the size of the tubing determine the volume of fluid that can be pumped. The volume that can be pumped is limited only by the volume of the input source.

Syringe Pumps

A Syringe Pump consists of a syringe attached to a motor driven pusher block which is usually driven by a stepper motor that moves in distinct increments. The syringe is filled with liquid and placed into the pump. As the pusher block moves, it presses the plunger of the syringe, which ejects the fluid. Some of these pumps can be programmed to allow for precise control. A variety of syringe pumps are available.

- Infusion/withdrawal (I/W) describes the syringe pump feature where the syringe plunger is held by the pusher so the motor can pull the plunger back, withdrawing fluid, as well as push the plunger to infuse it.

- A push/pull syringe pumps uses two syringes mounted back to back so movement of the pusher block simultaneously withdraws fluid into one syringe and infuses an equal amount from the other.

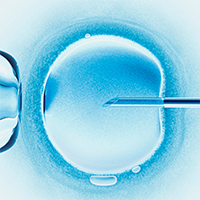

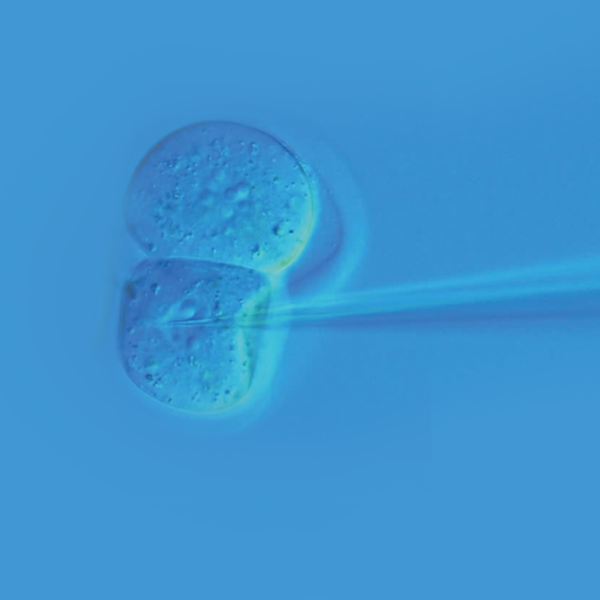

Pressure Injectors

Pressure Injectors use air pressure to move liquid in a micropipette or channel. The air behind the fluid in the pipette or channel moves the fluid. The pump uses a solenoid valve (electronic/mechanical switch) to control the flow of air. The pump consists of a regulator to control the pressure, a pressure gauge, an electronically controlled solenoid valve and a timer. These pumps are typically used for very small volumes in the picoliter to nanoliter range. The volume injected is controlled by the glass tip inside diameter (ID), pressure and time using the equation PV=nRT. Pressure (pascals) times volume (m3) equals the amount of gas (moles) times a constant times temperature (Kelvin).

Pump Type Comparison

| Pump | Peristaltic | Syringe | Pressure Injectors |

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Applications |

|

|

|

| Top Sellers |

Close