This website uses cookies to ensure you get the best experience on our website.

Read more

Glass Capillaries

-

April 30, 2013

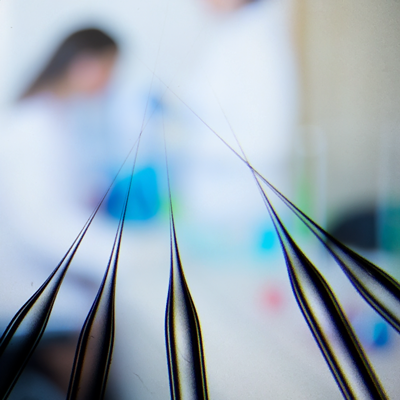

Two-barrel, 3-barrel, 5-barrel and 7-barrel glass capillaries are available at WPI.

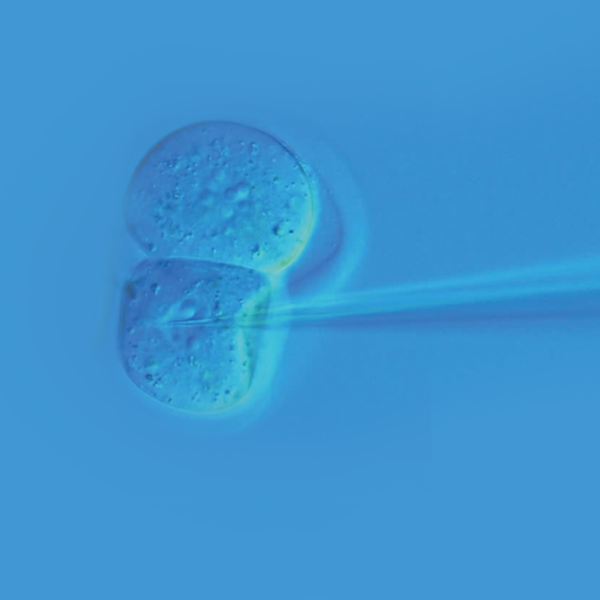

Multi-barrel configurations are designed especially for microiontophoresis. Because the capillaries are fused together during manufacturing, you will not need to twist them while pulling to seal the tips together. An inner filament in each barrel makes filling easy and fast.

Multi-Barrel Borosilicate Glass Tubing with Filaments

...moreOrder code Length Description -

April 29, 2013

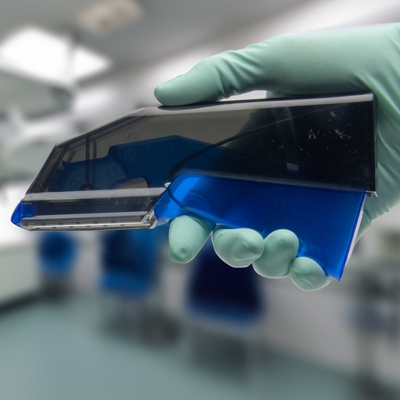

WPI offers a wide spectrum of high-quality glass capillaries. We take pride in our ability to ship your glass order within 48 hours. If you need a special glass that does not appear in our catalog, please call us. We will make every effort to provide it for you.

Fire-Polished glass capillaries are easier to insert into microelectrode holders without damaging the gasket. More importantly, fire-polished glass won’t scratch the chloridized wire used in a recording electrode. Fire-polishing does not affect the glass’s mechanical or electrical properties.

Borosilicate glass capillaries: Close dimensional tolerances assure...more

-

April 25, 2013

The physical properties of glass depend upon the chemical composition of the glass, as well as how the glass was manufactured. Glass has no set melting point, but four temperatures are of primary importance when discussing glass production.

-

Working Point - This is temperature that the glass is soft enough to work. At this temperature, the glass viscosity is 104 poises.

-

Softening Point - At this temperature, glass deforms easily, even by forces of gravity. The glass viscosity is 107.6 poises.

-

Annealing Point - When glass reaches the annealing point and remains for a few minutes, many of the internal stresses of the glass formation are obviated. During the annealing process, the glass is heated to the annealing temperature and then allowed to cool at a controlled rate. Glass that is not annealed is prone to crack or shatter with minor temperature fluctuations...more

-