This website uses cookies to ensure you get the best experience on our website.

Read more

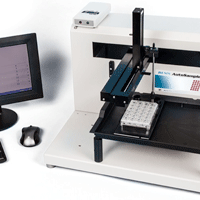

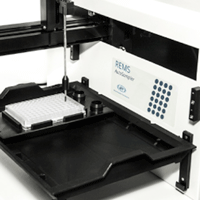

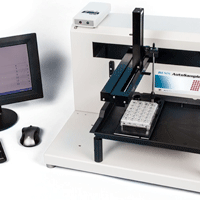

REMS Auto Sampler - HTS Robot

October 11, 2013

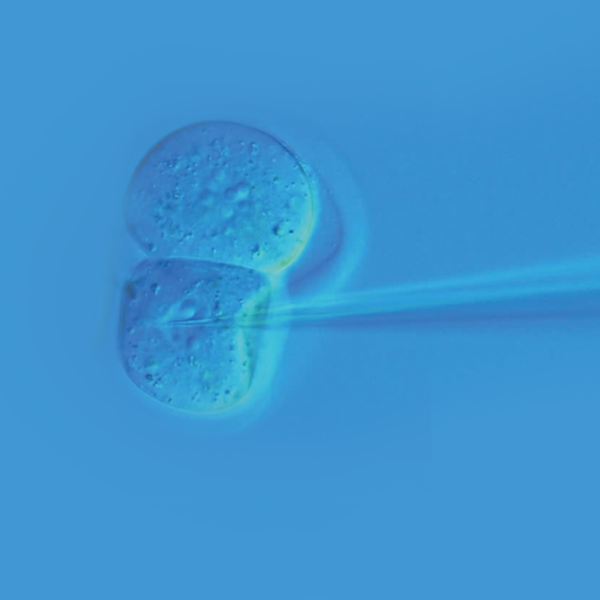

The REMS AutoSampler automates measurements of electrical resistance of transepithelial, transendothelial or Caco-2 cell membranes being grown to confluence on microporous filters of high throughput screening (HTS) 24- and 96-well microplates. It is a computer-controlled, tissue resistance measurement system that offers reproducibility, accuracy, flexibility and ease-of-operation for this kind of measurement.

The REMS AutoSampler automates measurements of electrical resistance of transepithelial, transendothelial or Caco-2 cell membranes being grown to confluence on microporous filters of high throughput screening (HTS) 24- and 96-well microplates. It is a computer-controlled, tissue resistance measurement system that offers reproducibility, accuracy, flexibility and ease-of-operation for this kind of measurement.Automated measurement of tissue resistance in cell culture microplates provides the important advantages of speed, precision, decreased opportunity for contamination and the instant availability of measured resistance data on a computer. These measurements are useful in applications such as drug bioavailability studies and studies on the mechanisms of drug transport.

The main components of the REMS AutoSampler include:

- Robotic sampler that moves the electrode over each well of the microplate

- Electrode which is located on the robotic arm

- Base plate for the 24-and 96-well tray

- Windows-based data acquisition card

- REMS interface unit

- REMS software to operate the system on a Windows-based computer

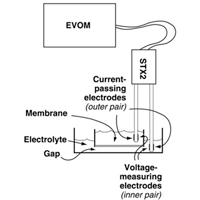

The REMS AutoSampler automates TEER measurements previously made with WPI's EVOM2 Epithelial Voltohmmeter. Automated tissue resistance measurements up to 20kΩ can be performed on 24- or 96-well HTS microplates. Microplates presently supported include the Corning Costar HTS Transwell-24, Falcon HTS Multiwell insert systems, and Millipore Multiscreen™ CaCo 96-well plate. The REMS AutoSampler is designed to facilitate integration with other robotic systems. Special locating bars are installed on the REMS base platform that allow other system robots to place an HTS tray into a precise location on the REMS base.

The REMS AutoSampler automatically measures and records tissue resistance from a user-specified matrix of culture wells on the microplate. According to the specified sequence, the robotic arm moves over the identified wells taking TEER measurements. By means of a x-y-z locating system, the electrode-containing arm is positioned precisely and reproducibly over each well. The ability of the REMS AutoSampler to reproducibly and precisely locate the electrode results in highly reproducible TEER measurements. TEER measurements are stored in the computer as the electrode moves from one well to the next. The Windows-based software provides user-friendly features to acquire, display and store the tissue resistance measurements.

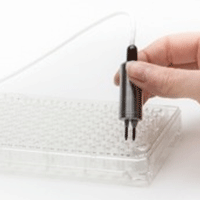

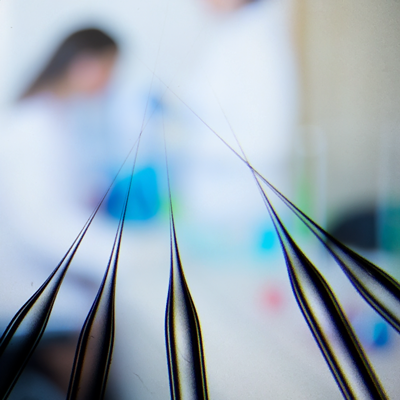

The REMS electrode is compact and robust in design. Each of two rod-shaped probes, 1.5mm in diameter, consists of a pair of electrodes: one electrode for injecting current and the other for measuring the voltage. The use of two pairs of electrodes eliminates the error caused by the electrode-liquid interface. To take a measurement, the robot inserts one probe into the center of the filter well and the other into the opening slot of the 24- or 96-well plate. The use of AC current to measure resistance provides several advantages over DC current, including:

- Absence of offset voltages on measurements

- There is a zero net current being passed through the membrane, and therefore it is not adversely affected by a current charge

- No electrochemical deposition of electrode metal.

The REMS AutoSampler also features a rinse and calibration check station. If occasional rinsing of the REMS electrode is required, it maybe sent to a rinse station by pressing the rinse station button on the menu bar.

Close